High Voltage Safety

HYDRAPULSE® TECHNOLOGY

Superior Safety for High Voltage Hydraulic Systems

Never before has the fluid power industry undergone such a massive push towards electrification. It is happening in every sector and every part of the globe. Consumers want all the benefits that come with electrification, such as control, noise reduction, cleanliness, simplicity, etc. What we also need to keep in mind is that with electrification, comes the inherent safety risk of high voltage. High voltage battery safety is vital when designing, installing, maintaining and repairing these systems.

For years, Terzo Power Systems has focused on innovation across the board for fluid power. Much of this effort was to ensure safe and reliable operation. The industry is still far from mature and many best practices are still not in place. We have seen many customers attempt extremely unsafe development work to try and hybridize or electrify their system. Packed into every product we make is a deep and seamless set of safety measures built in.

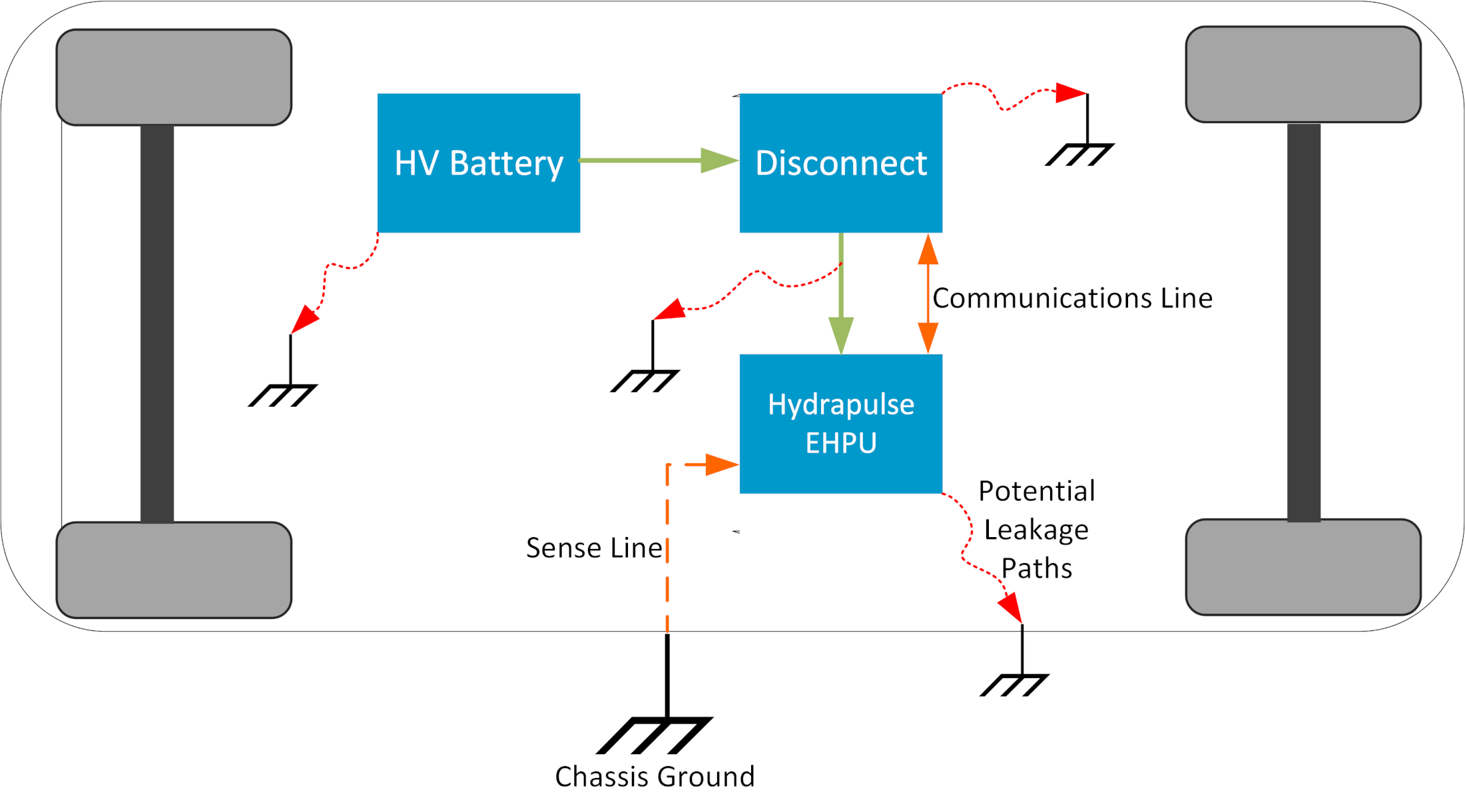

Stray voltage sense technology (isolation monitoring)

There’s no room for error with high voltage safety and that is why we have implemented automotive developed voltage sense technology. This system, which is embedded on every high voltage Hydrapulse, detects when any stray voltage levels are present which would cause a safety hazard. This detection then immediately shuts down operation of the system and/or sends a signal out to battery disconnects (in the case of on-vehicle applications) or other means of alarm.

This system uses AEC-Q100 certified integrated circuits that meet stringent Automotive Electrical Council requirements. This type of technology is required when applying an unearthed IT system such as a DC battery on an electric or hybrid vehicle.

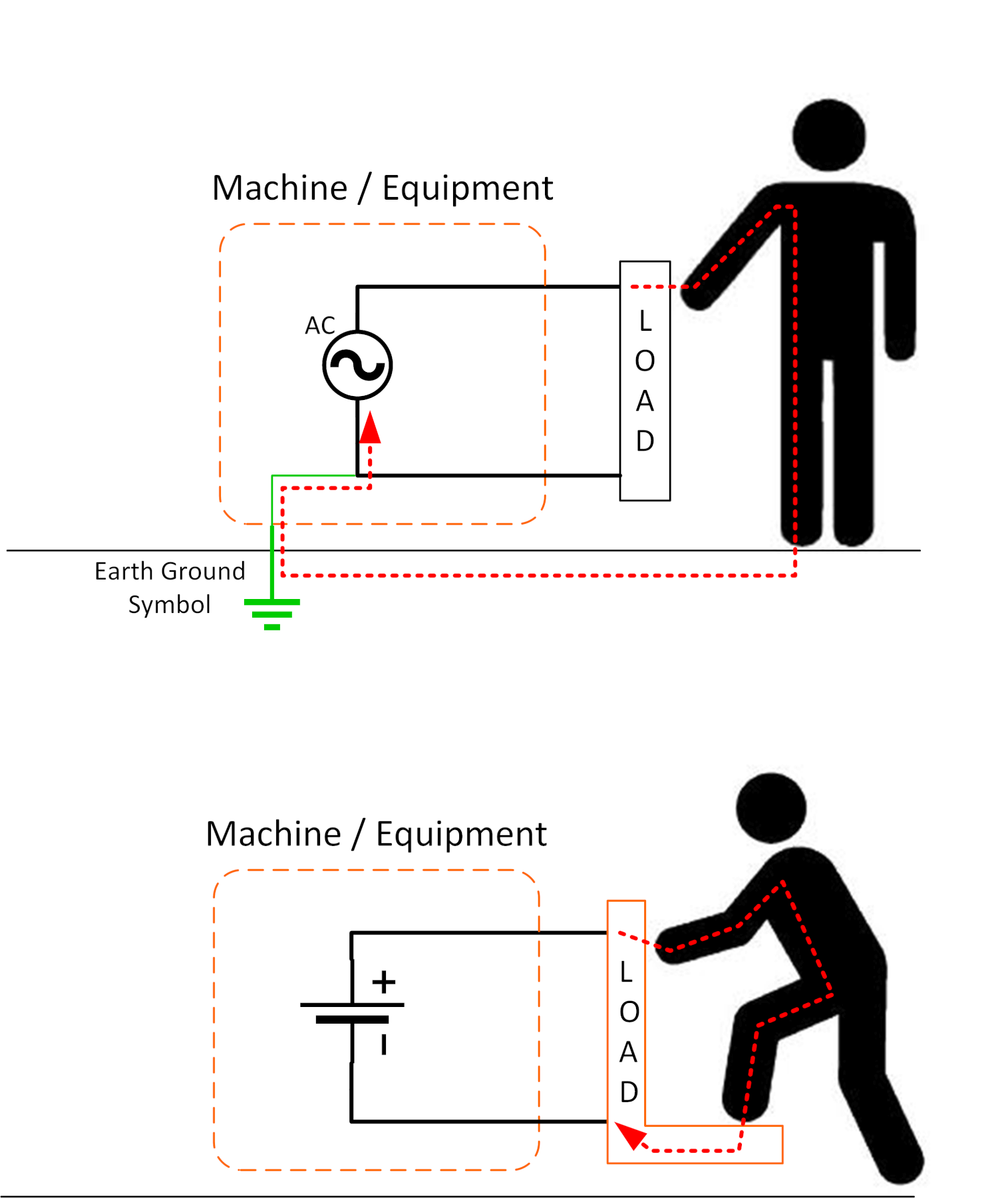

Know the difference between AC and DC

Everyone must know the difference between AC and DC systems. In AC systems, anything that touches the ground can be a potential return path for electricity whereas in DC systems, the return path can be much different.

On vehicles, low voltage 12vDC systems have often used the chassis for the ground return path. This has allowed for simplification of wiring systems and the understanding that the electrical system is relatively safe and not something to be concerned with.

This is not the case once we move up in voltage. Anything over 50v is not considered “touch safe” anymore and depending on what standard you refer to, this threshold can be as low as 42 volts. Therefore, high voltage battery safety must be accounted for with all components in the system.