Hybrid Sno-CAT

While I was working for a large fluid power integration company in my previous life, I realized that our industry had to begin making strides towards high efficiency power platforms. If you walk around CON-EXPO for very long, you will see that nearly every single piece of off-highway equipment is the same: hydraulic pumps directly coupled to a large diesel engine. This was all fine and dandy until the price of diesel started creeping up, the particulate emissions (PM) from diesel engines started to be highly regulated, the noise from these systems became a nuisance, and a worldwide push towards an electric future kicked into overdrive. These issues meant that the cost effective, reliable, and torque dense diesel engine could not be the only game in town.

Well, it just so happens that a diesel engine is REALLY good at providing the torque hungry rotation that a hydraulic pump craves! You cannot simply replace a diesel engine with a gas engine…. NOPE.

Enter the power dense, clean, and quiet permanent magnet electric motor (PM). Its development has been accelerated initially by the likes of the Prius and more recently by the likes of Tesla and others who have developed high power, mobile hardened PM motors.

That’s great and all, but how are we supposed to power the heavy-duty behemoths that checker the typical construction site? We the answer in part is a HYBRID. So I took the opportunity that exists in the form of TIER IV engine upgrade and looked for an OEM that is facing the challenge of cramming a TIER IV into a TIER III chassis, easier said than done. We chose a Sno-CAT as a great vehicle to propose a gas hybrid system to. You can’t get a cooler (pun intended) vehicle to hybridize!

So we set about making the first hybrid-electric sno-CAT machine!

-

Hybridized Chassis! -

Manny at the controls -

Prototype Hybrid Sno-CAT vehicle. -

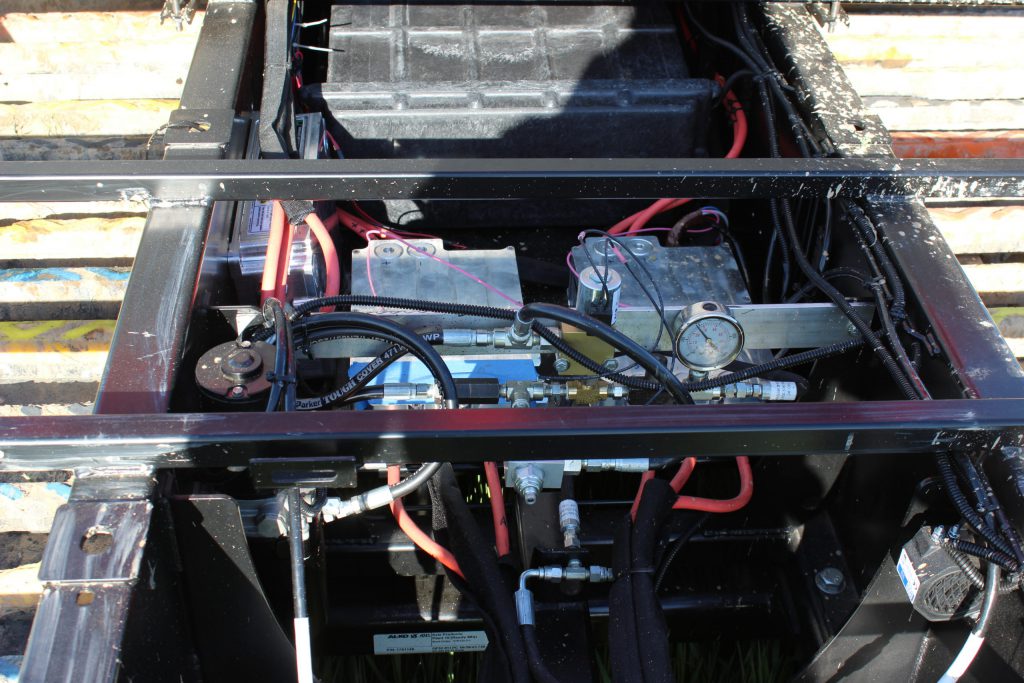

Hybrid Power Train in Sno-CAT -

100KW PM motor / Engine Combo -

Manny on the Laptop

We successfully converted this 150HP diesel engine machine to a 60HP hybrid-electric machine.

The 57HP Kubota WG1605-G engine is fully electronic controlled via J1939 CANBUS which made it easy to integrate into our custom control system. The engine only cares about keeping the Li-ion Battery pack topped up and only runs in its most efficient power RPM band. It would simply start and stop as needed depending on how hard you were driving the machine.

We implemented a Series Hybrid architecture which provides for flexibility in powering traction motors, hydraulics, auxiliary functions, etc off of the high voltage DC battery bus.

This project was an amazing achievement and provided the foundation and hands-on learning needed to begin a company dedicated to the development of the key missing pieces of technology in the off-highway industry. Over 5 years ago, I founded Terzo Power Systems with the singular goal of making hybrid or electric powered heavy-duty vehicles a reality, correction, a cost-effective reality! We now are manufacturing the Hydrapulse® Smart Hydrapulse Power Unit that can be used in any off-highway vehicle, we are about to go into production on our High Voltage Safety System under our Hevi Systems brand name, and we are continuing to push the envelope to enable small and mid size OEM’s to electrify and hybridize their vehicles. So enjoy a few videos from this project:

Mike Terzo

Founder and CEO of Terzo Power Systems, LLC.