Overview

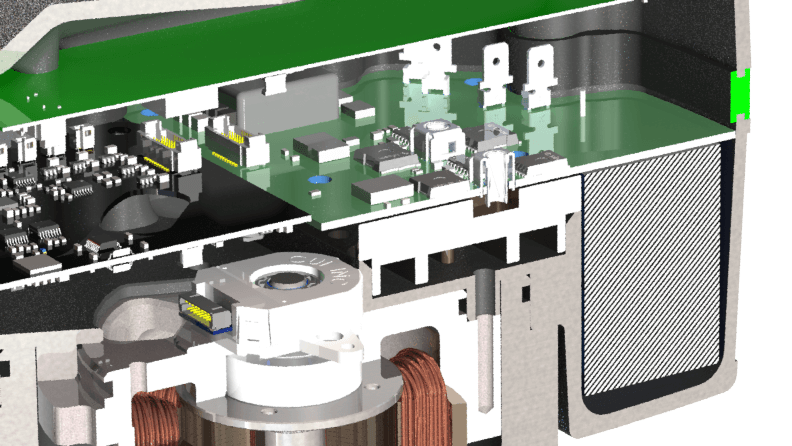

Hydrapulse® Technology

Hydraulic Pump Engineered to Last

The Hydrapulse, our permanent magnet motor hydraulic pump, was designed from the start to operate in the world’s most extreme environments.

Never before has a fluid power product been engineered from scratch with a clean sheet thinking on the issues we face everyday. Our team brings advanced technologies from across multiple industries to integrate into the most powerful hydraulic power system available.

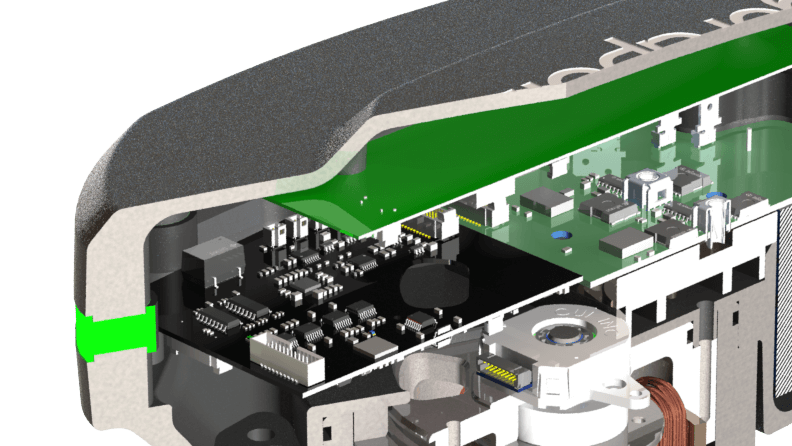

Automotive Grade Electronics

When you are building a house, it is critical to start with a strong foundation, or it won’t stand the test of time. The same thing goes for electronics. You must start with the correct foundation, and that foundation is using automotive grade components proven to withstand the harshest conditions. From the smallest resistor to the largest capacitor, every component must be of the highest quality.

Using non-automotive grade components leads to shorter lifespan, higher failure rates and other durability or reliability issues. Standing up to the shock and vibrations is a must and withstanding withering temperature extremes is a necessity. That’s why we have certified the Hydrapulse to the rigorous SAE J1455 automotive testing standards.

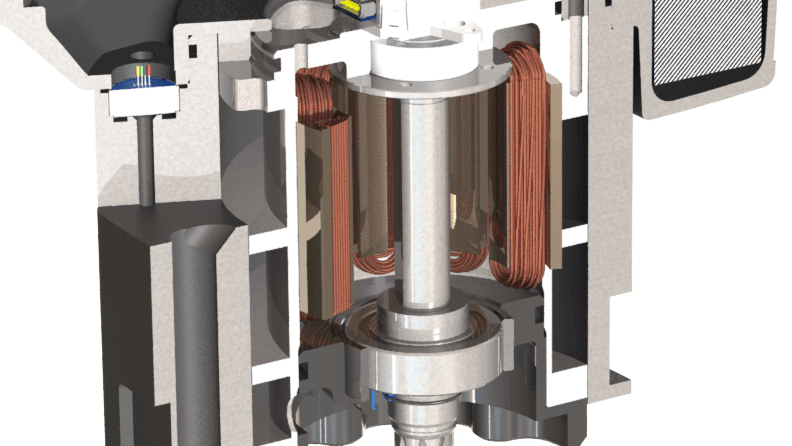

Permanent Magnet Motor

Permanent magnet motors are one of the most compact, efficient and powerful technologies to be commercialized in the last few decades. They have had a profound impact on the electrification of almost every industry. It’s what is inside a Tesla Model 3 and what powers more and more appliances, pumps and systems everyday. No longer only the realm of advanced servo-driven motion control systems, the permanent magnet motor is now hitting prime time.

We have developed a fully custom, ground up motor that can provide near-instantaneous power to a hydraulic system – a permanent magnet motor hydraulic pump, the Hydrapulse. Our low inertia motor system was developed specifically for the mobile industry and can operate in the most extreme conditions, even underwater!

This type of motor can provide a constant torque at even zero speed, which allows us to provide fluid flow, pressure and direction in a power-on-demand function thereby significantly increasing your system’s efficiency.

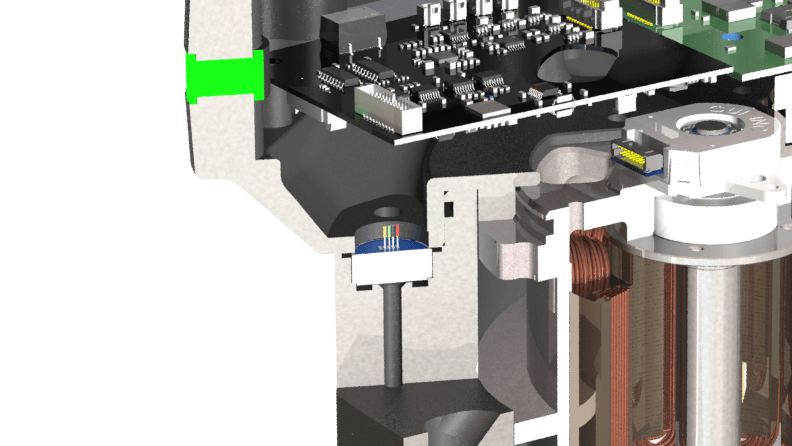

Mobile Hardened Inverter

In the middle of the Hydrapulse is a beating heart, or more precisely, a switching heart. The switching transistors are the primary feature of a motor inverter. Sometimes called other names, the inverter houses the power electronics that allow us to control our permanent magnet motor with high precision. We can control our motor speed and torque so precisely that open loop hydraulic cylinder positioning is now possible for many applications. Imagine knowing your cylinder’s position without a position sensor that adds cost and complexity to your system!

We utilize two forms of switching transistors: MOSFETs and IGBTs. Our MOSFETs are automotive grade transistors optimized for our low voltage lineup whereas our IGBT versions are optimized for our high voltage applications.

Integrated Pressure Transducers

Here’s where things start to get really cool! We embed two digital pressure transducers into each Hydrapulse. One sensor for each output. This allows us to know the pressure output at every given instant and use that information to close the “pressure loop” onboard our product giving our customers full pressure control, i.e. “pressure compensation mode.”

You can simply command a pressure setpoint on the fly and the Hydrapulse will provide that pressure (provided there is enough resistance on your load). We also broadcast the pressure on the CAN communications bus for our customers to use for programming logic, troubleshooting, diagnostic, etc.