Hydrapulse®

Features | Benefits

The Fluid Power Industry Has Never Seen a Product Like the Hydrapulse

The Hydrapulse is a complete electro-hydraulic system with an integrated motor, controller and closed-loop feedback that enables the electrification of a broad range of equipment in the industrial, mobile, machine tool and trucking markets.

Hydrapulse EHSU & EHPU Overview

Electro-Hydraulic System Steering Unit

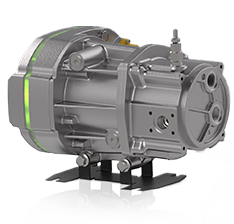

The Hydrapulse EHSU is a rugged electro-hydraulic system with a smart pump unit designed for mobile steering assist and e-steering applications.

Electro-Hydraulic System Power Unit

The Hydrapulse EHPU is a rugged electro–hydraulic pump unit designed for industrial and mobile applications.

Hydrapulse Features

- Control

- Cooling

- High voltage safety

- Inverter switching

Electro-Hydraulic System, A New Level of Control

The control of fluid power is no longer about valves, it’s about software. Software-controlled hydraulics introduce an entirely new level of control. With the Hydrapulse, an infinite level of control is now available without the complexity, lead time, maintenance problems, troubleshooting and cost of traditional hydraulic control valves.

REDUCE HEAT GENERATION UP TO 80%

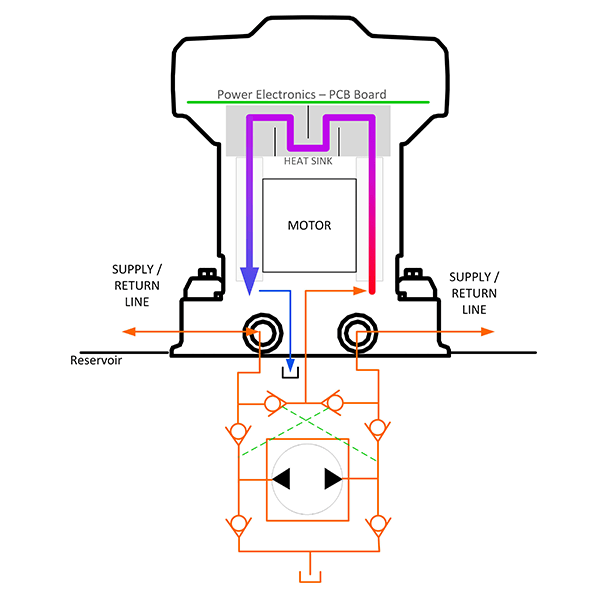

It’s a thermal game when it comes to designing products for the harsh fluid power industry and when heat is generated, you must do something with that heat to get it out of the system or off of the vehicle. What makes our technology completely unique is that the Hydrapulse is self-cooling, meaning that we actually utilize the hydraulic fluid to remove the heat from our power electronics (transistors) and our motor.

LOW PRESSURE RETURN TECHNOLOGY

Our patent pending low pressure return cooling technology allows us to deliver a plug and play hydraulic power unit that does not require complex cooling via an external liquid cooling system, cooling fan, external fins, etc. We simply use the low pressure return oil from the hydraulic work function or valve bank to cool our motor and our electronics. It’s simple, yet groundbreaking technology.

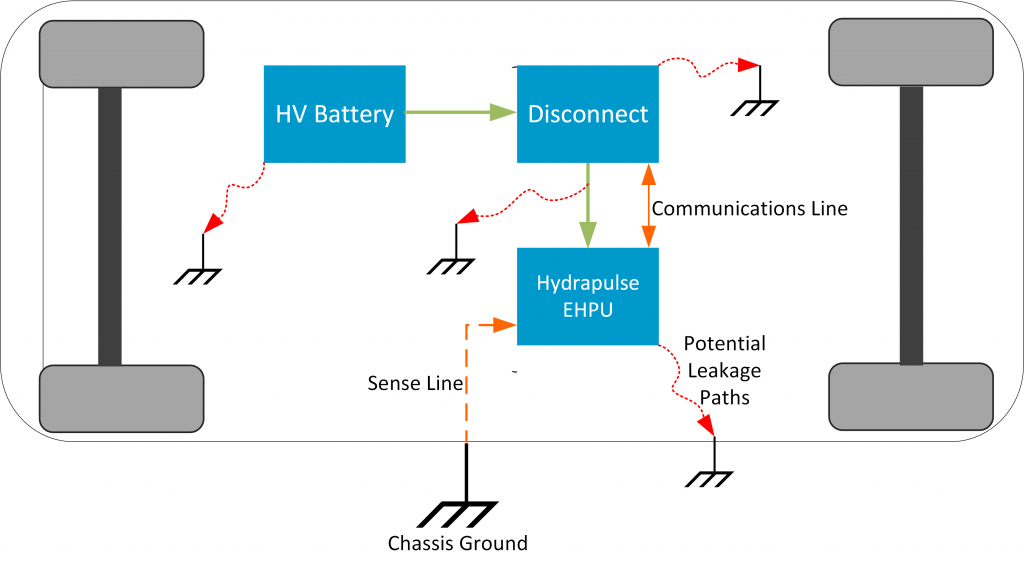

SUPERIOR SAFETY FOR HIGH VOLTAGE

Never before has the fluid power industry undergone such a massive push towards electrification. It is happening in every sector and every part of the globe. Consumers want all the benefits that come with electrification, such as control, noise reduction, cleanliness, simplicity, etc. What we also need to keep in mind is that with electrification, comes the inherent safety risk of high voltage. High voltage battery safety is vital when designing, installing, maintaining and repairing these systems.

VOLTAGE SENSE CIRCUIT

There’s no room for error with high voltage safety. That’s why we integrated automotive-developed voltage sense technology. This system, which is embedded on every high voltage Hydrapulse, detects when any stray voltage levels are present which would cause a safety hazard. This detection then immediately shuts down operation of the system and/or sends a signal out to battery disconnects (in the case of on-vehicle applications) or other means of alarm.

ADVANCED HYDRAULIC INVERTER TECHNOLOGY

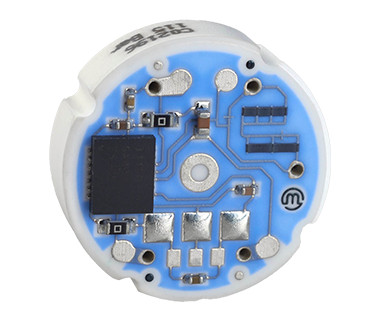

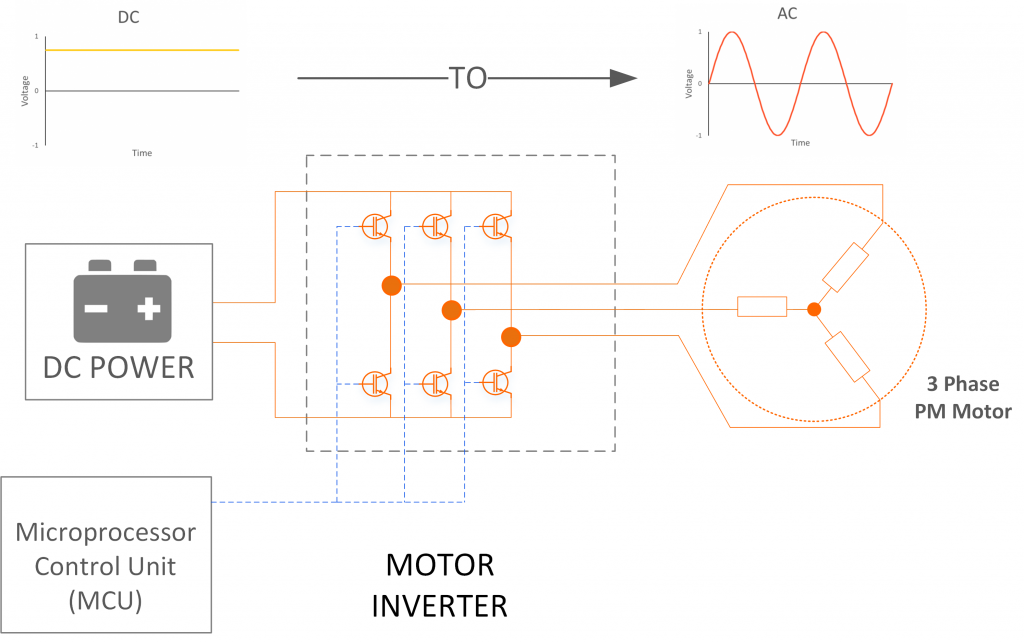

At the heart of the Hydrapulse is what we call the inverter. This is the component that controls the speed and torque of our permanent magnet motor. An Inverter falls under the power electronics discipline of electrical engineering and serves the purpose of converting the power from a battery (in the case of a mobile vehicle), or the power coming in from the grid (line power) and controlling its frequency and current to control our motor.

MOTOR CONTROLLER

While Inverters are used in many industries (such as solar inverters), the Inverter we have developed is actually a motor inverter, meaning it’s an inverter specifically designed to control a three phase permanent magnet motor. When we convert the DC power into an AC waveform, we can now control the frequency and amplitude of the AC waveform. This allows us to vary the AC power to the PM motor thus controlling its speed and torque.

Hydrapulse Benefits

- Customization

- Durability

- Energy efficiency

- Size & weight reduction

Designed For Any Application

Every application is different, this holds true more than ever in the fluid power industry! The Hydrapulse was designed from the ground up to allow for customization. We can quickly customize connectors, firmware, housings and pumps for customers with volume applications.

Custom 800V DC Coolant Pump for Electric and Hybrid Vehicles

Whether you want 25 units with a custom change or 2500 units, we can make sure you have the best solution for your applications.

RUGGED DESIGN FOR SUPERIOR DURABILITY

The Hydrapulse was designed from the start to operate in the world’s most extreme environments. Never before has a fluid power product been engineered from scratch with a clean sheet to rethink the issues we face every day. Our team brings advanced technologies from across multiple industries to integrate into the most powerful hydraulic power system available.

SHOCK AND VIBE

When it comes to tough environments, the mobile industry is one of the toughest. Our products have to withstand anything our customers can put it in. The shocks that a mobile vehicle can put its components through can be torture so we had to be ready.

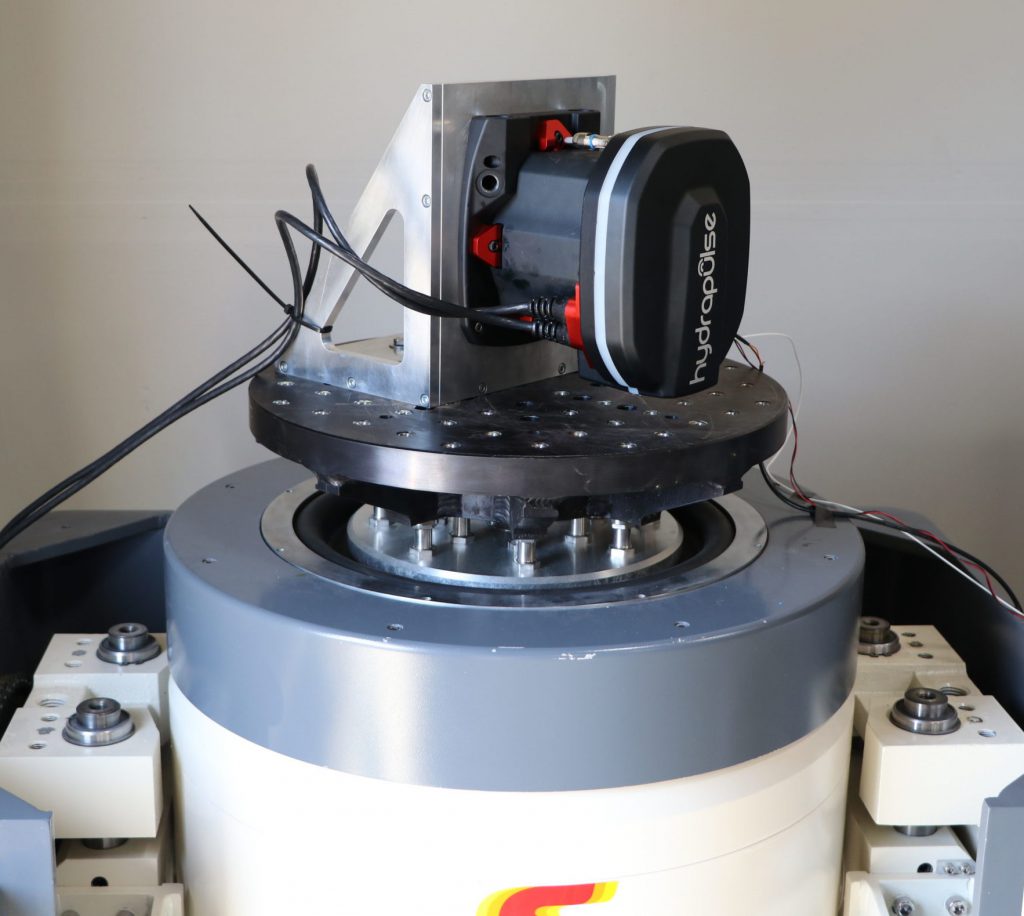

That is why we invested in our own testing equipment. We installed an electro-dynamic shaker, a temperature and humidity test chamber and a dynamometer to give us the ability to run the most rugged tests we could imagine.

ENERGY EFFICIENCY ON DEMAND

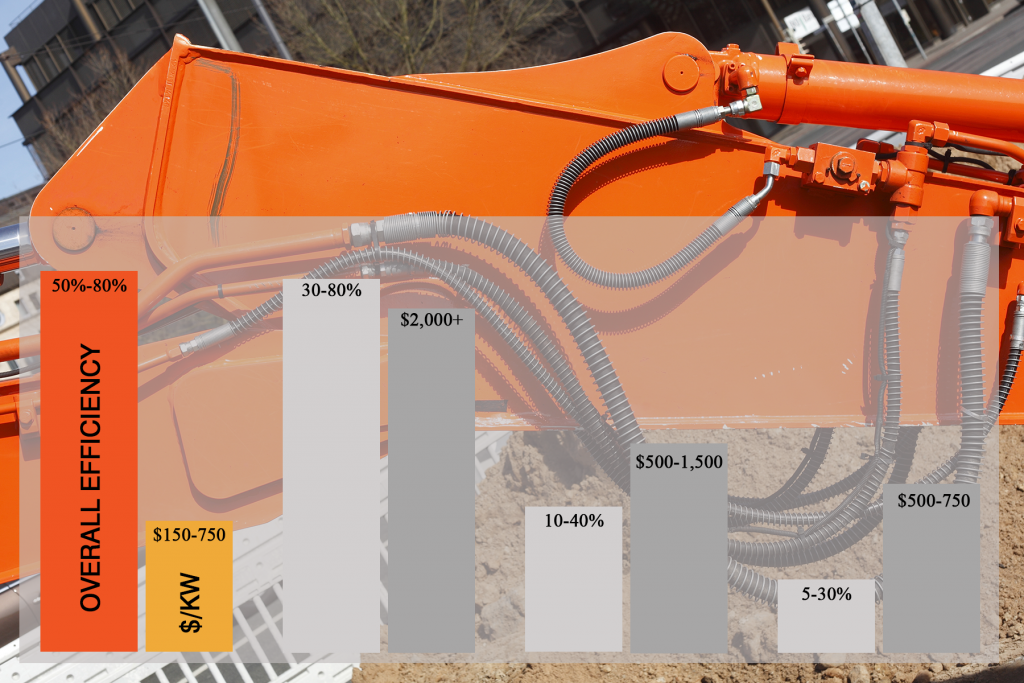

Saving energy has never been easier. When you use Hydrapulse products, you no longer need to think about how to make your system more efficient, we’ve done that part for you.

Servo (permanent magnet motor) driven hydraulic systems are not new, in fact they’ve been around for decades. The ability for hydraulic pumps driven by a permanent magnet motor to achieve significant energy savings is also well-documented. Energy savings of over 82% is common in applications where there is a long dwell cycle such as injection molding, rubber molding, or other press type applications.

ADVANTAGES OF EFFICIENT HYDRAULICS

So why haven’t these types of systems been more widely adopted yet? The challenges are simple: These systems are too expensive, too complex and need specific skills to design, install and troubleshoot. Yet permanent magnet motor-driven hydraulic systems offer substantial benefits, including:

- Precise control

- Up to 200% overload capability

- High efficiency

- Reduced oil requirements

- More compact size

- Significant noise reduction

- Heat reduction

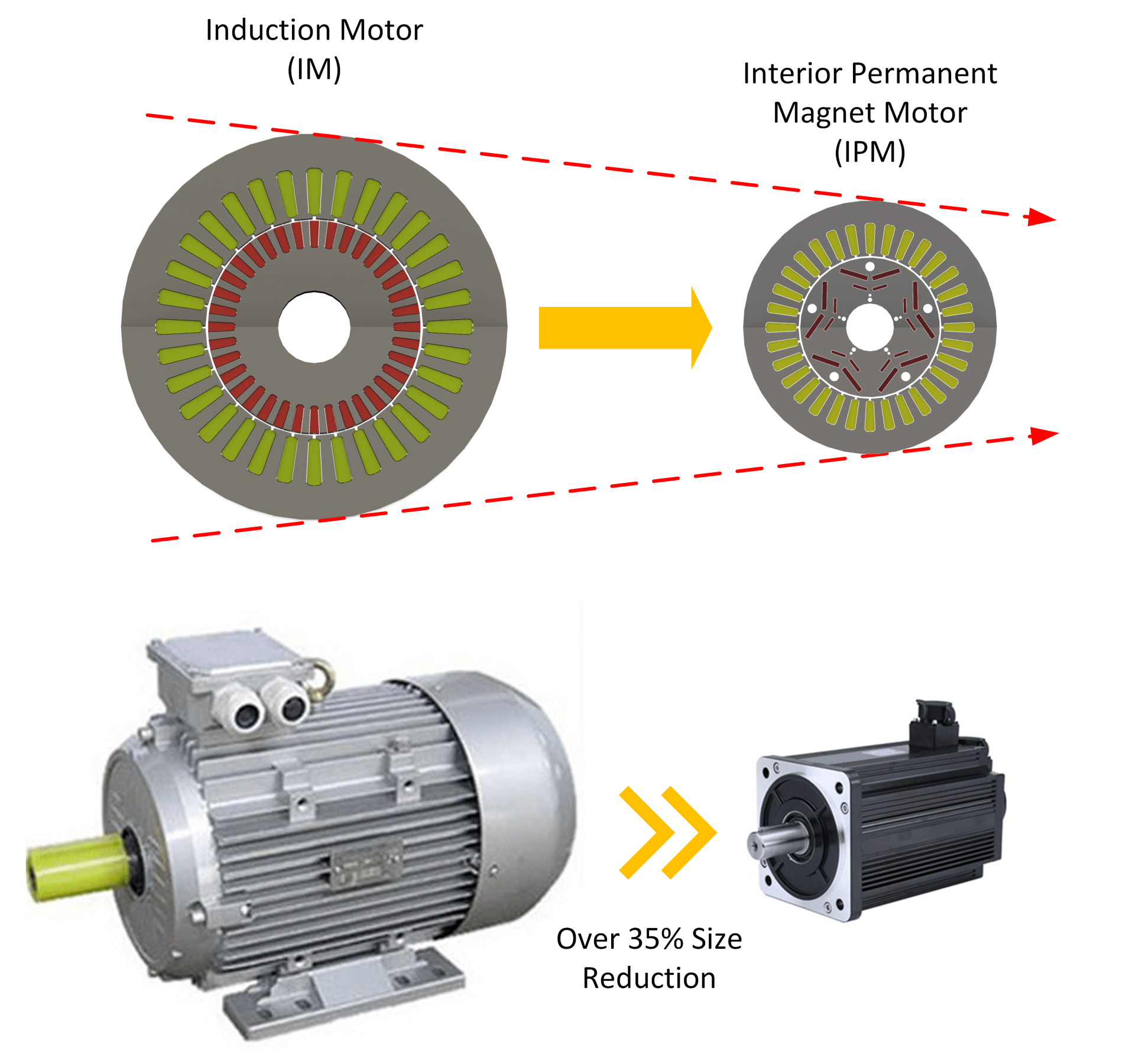

UP TO 86% SIZE REDUCTION

The Hydrapulse was developed on industry-proven, power-dense technology that, until now, has been too expensive to incorporate into hydraulic power units. At the top of this technology list is our permanent magnet (servo) motor. Servo motor hydraulic power units have been around for decades but have only made headway into markets that have extremely forgiving duty cycles such as the injection molding industry, where extremely long dwell times under pressure have made an ROI business case for servo hydraulics.

UP TO 87% WEIGHT REDUCTION

By looking at a complete hydraulic power system and engineering it for the purpose and function it needs to accomplish, Terzo Power Systems has disrupted the traditional way of creating fluid power and provides an industry record-breaking lightweight hydraulic pump for all applications.