Durability

Hydrapulse® Technology

Rugged Design for Superior Hydraulic Pump Durability

The Hydrapulse was designed from the start to operate in the world’s most extreme environments. Never before has a fluid power product been engineered from scratch with a clean sheet to rethink the issues we face every day. Our team brings advanced technologies from across multiple industries to integrate into the most powerful hydraulic power system available.

Our Hydraulic Pump Durability – Begins with SAE J1455

The Society of Automotive Engineers (SAE) provides the benchmark standard of testing for products that need to withstand the mobile industry. And the gold standard of this testing is J1455 – Recommended Environmental Practices for Electronic Equipment Design in Heavy-Duty Vehicle Applications. So we test everything to this standard, as a minimum.

We also have ongoing testing to many other standards. In fact, our testing will never actually end. Our ongoing durability test stand runs continuously night and day to ensure that we will be able to meet the needs of our customers. See a snippet from our testing in the video below.

SAE J1455 Testing Overview

Temperature – Extremes,Thermal Shock, Thermal Stress Cycling, -40°C to °85C

Humidity – 0 to 100% throughout temperature extremes

Salt Spray / Immersion – Spray and salt water immersion testing

Steam / Pressure – Steam cleaning and pressure washing testing.

Fungus – Fungal growth testing

Altitude – Low pressure testing

Gravel Bombardment – Speaks for itself!

Mechanical Shock – Drop test, harness shock, and more.

EMI / EMC – Electromagnetic noise

Shock and Vibe

When it comes to tough environments, the mobile industry is one of the toughest. Our products have to withstand anything our customers can put it in. The shocks that a mobile vehicle can put its components through can be torture so we had to be ready.

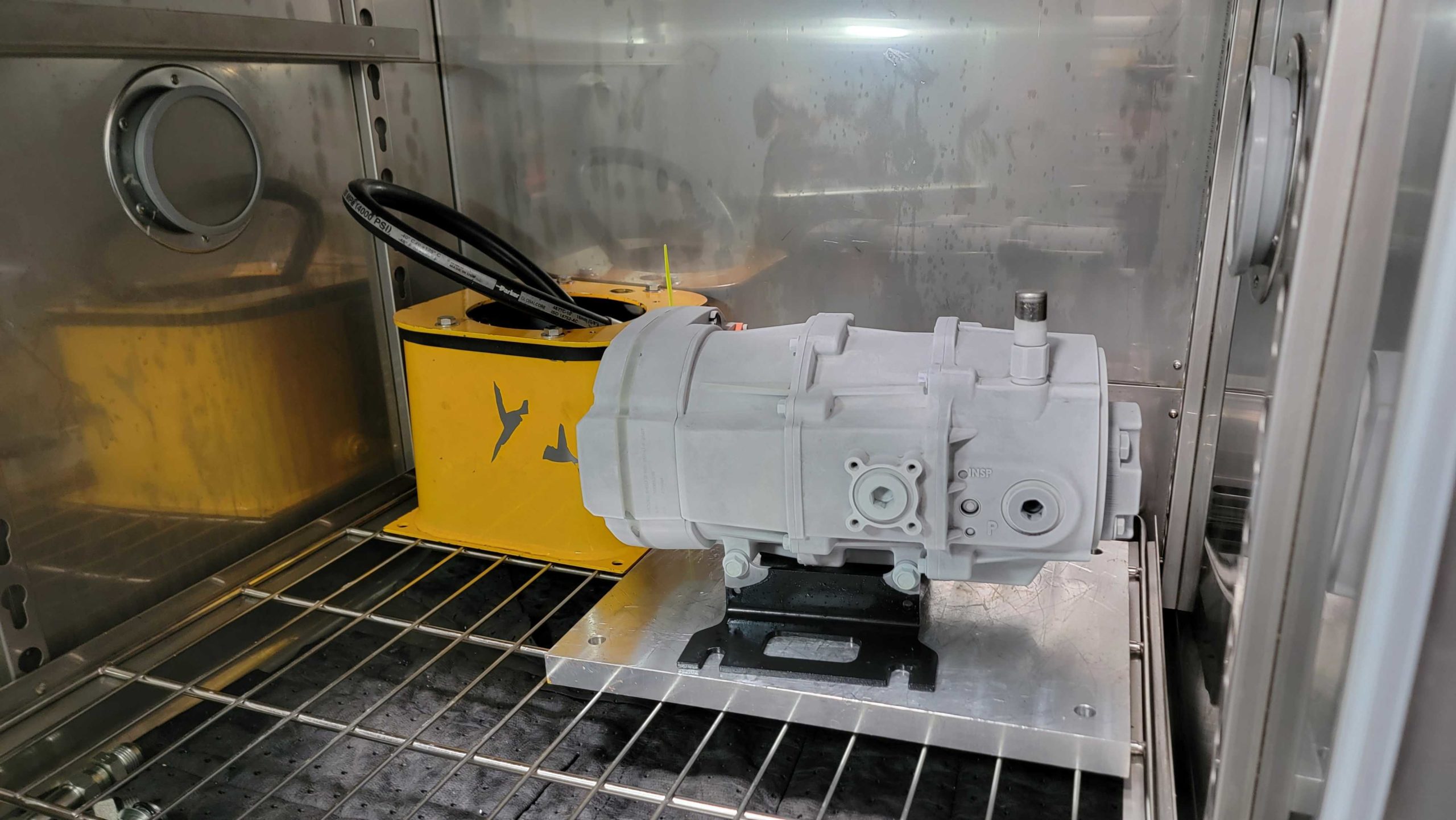

That is why we invested in our own testing equipment. We installed an electro-dynamic shaker, a temperature and humidity test chamber and a dynamometer to give us the ability to run the most rugged tests we could imagine.

Extreme Temperatures

The Hydrapulse is designed and manufactured to operate in temperature extremes. This could be an asphalt paving machine operating in the Arizona summer sun with an ambient temperature of 110° F or a pipeline valve HPU operating above the arctic circle where the daytime high might reach -20°F. No matter the temperature, we must be able to operate, day in and day out.

We have tested the Hydrapulse to the most extreme temperatures. This includes temperature shocks from 120°C to instant ice water bath to make sure our customers will have the reliability they need. We have also tested at 100% humidity in case you want to run our stuff in the jungle!

Testing Under Extreme Pressure

Look, we have all seen it happen, when a machine comes back to the shop from the field and needs to be cleaned, the “new guy” grabs the commercial rated 3000+psi heated pressure washer and is determined to get the last little bit of dirt out of every nook and cranny.

Since that happens in the real world, that’s what our team had to test. Yes, we test to meet SAEJ1455 Automotive Environmental Standards. When we’re done with those, we test to “real world” standards.