Maintenance

Hydrapulse® Technology

Superior Up Time, Fewer Repairs and Reduced Downtime

When it comes to hydraulic systems, maintenance is always talked about, yet rarely performed. Like any mechanical system, hydraulic system maintenance is critical to long life and reduced downtime.

The problem with maintenance in the fluid power industry is the extreme diversity of system designs, installation and component types. You could make a pretty solid bet stating that virtually no two hydraulic systems are the same even when they are built to the same prints. The maintenance requirements are always different and complex. This complexity translates into a lack of maintenance, since technicians responsible for industrial factories or vehicle owners typically do not know all the particulars of a specific system.

The next problem with hydraulic system maintenance is troubleshooting. A worn pump that needs maintenance, a filter in bypass, an HPU that continuously operates over the oil breakdown temperature are all issues that a technician would need to identify (i.e., troubleshoot) in order to perform correct maintenance.

When maintenance is performed, the machine downtime can be substantial or the lead time waiting for a replacement component can be long.

To make matters worse, everybody and their dog has an IOT solution that claims to make predictive maintenance a simple endeavor and one that can seamlessly and virtually without effort be integrated into a system at any point. Well, we all know this is not true, and the IOT debate will rage on for now.

But the maintenance issue has been top of mind during the development of the Hydrapulse technology. We have striven for simplicity in design, installation and repair. We accomplish superior troubleshooting and maintenance capability with the features noted below.

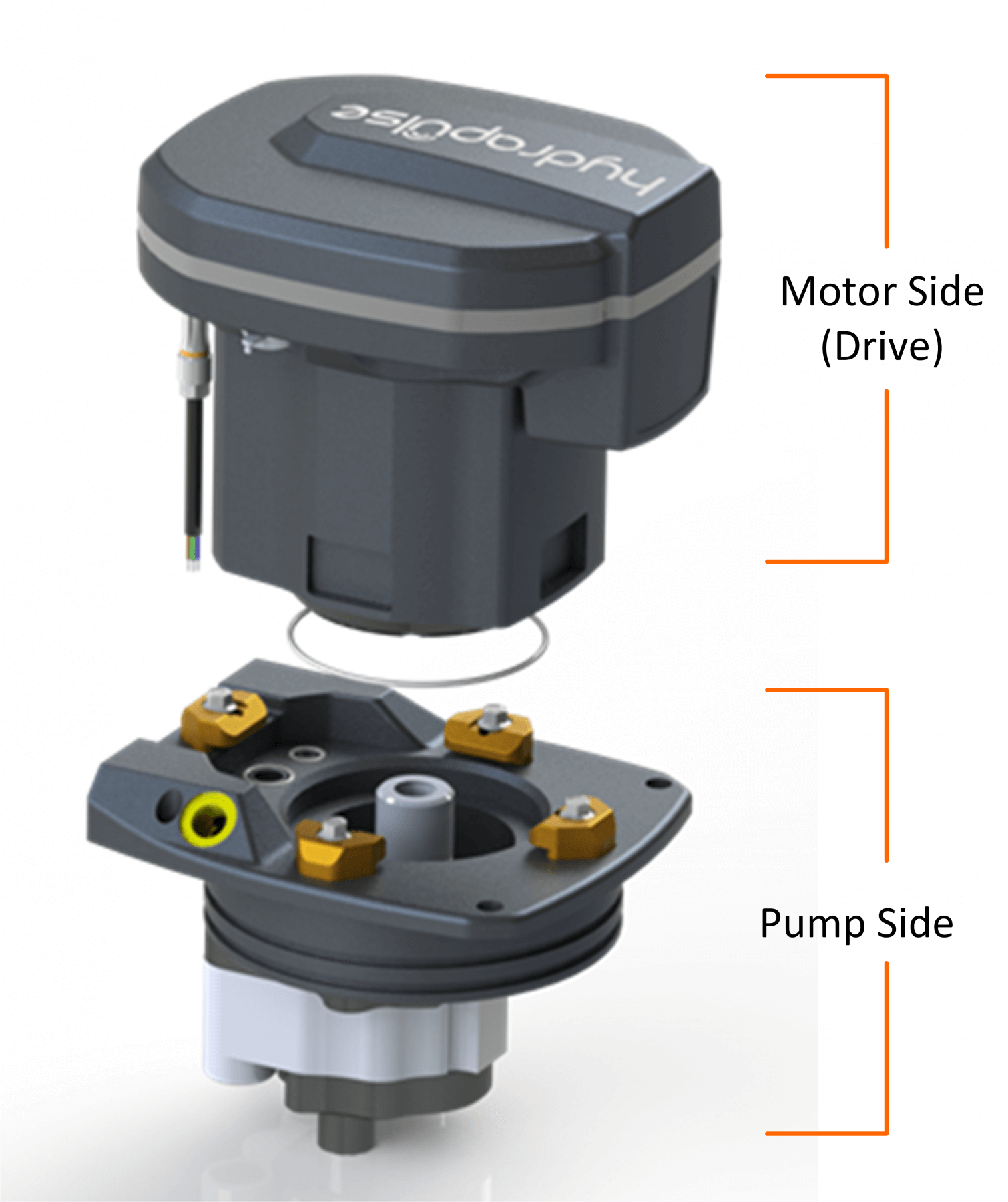

Motor Side / Pump Side

The Hydrapulse is simple to install and maintain with our unique integration of a motor side and a pump side of the EHPU system. Simply install the pump side on your reservoir independent of the motor side.

What this allows our customers to do is to simply replace the motor side or the pump side in a matter of minutes if there is an issue. This makes equipment down time a fraction of a traditional system.

What this design also allows for is a diverse amount of customization on the pump side for various hydraulic functions without any change to the motor side. Terzo Power Systems can quickly provide customer and application specific hydraulic performance without any change to our electronics, controls, etc.

Diagnostics Built-in

Diagnostics can simplify machine installation and troubleshooting. Knowing the status of key features of the Hydrapulse allows our customers to quickly and easily understand the system dynamics and apply that understanding to their application to support their goals.

Make sure to reach out to our engineering team to learn about the full capability of our diagnostics. Also refer to our O&M manual for a full description of command, alert, warning and fault messages that can be configured on the Hydrapulse.