Inverter Switching

Hydrapulse® Technology

The Most Advanced Hydraulic Inverter Technology Available

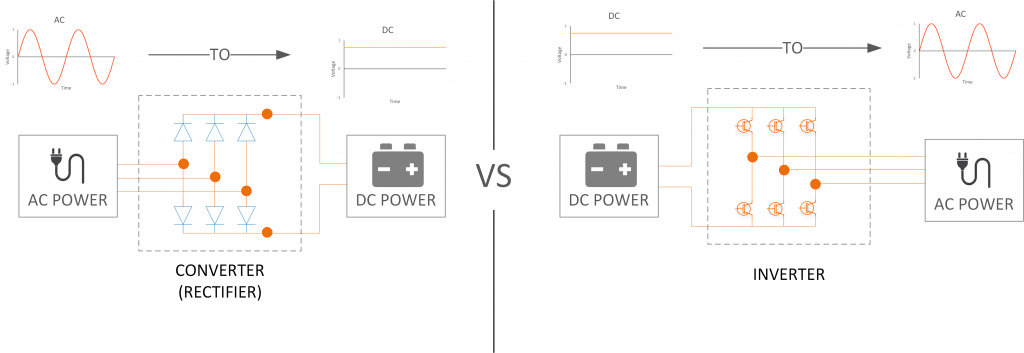

At the heart of the Hydrapulse is what we call the inverter. This is the component that controls the speed and torque of our permanent magnet motor. An inverter falls under the power electronics discipline of electrical engineering and serves the purpose of converting the power from a battery (in the case of a mobile vehicle), or the power coming in from the grid (line power) and controlling its frequency and current to control our motor.

We call it an inverter but it’s also called a lot of other names: Variable Frequency Drive (VFD), Frequency Converter, Traction Inverter, Motor Controller, Servo Drive and many more. But the mobile industry has settled on inverter for the most part, so that’s what we call it.

Motor Controller

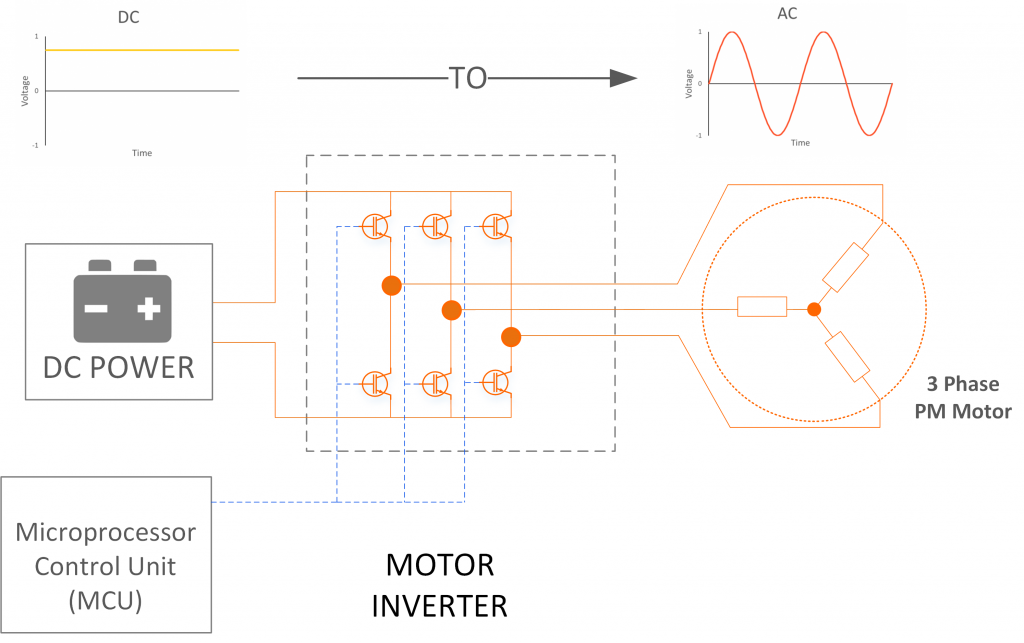

While inverters are used in many industries (such as solar inverters), the inverter we have developed is actually a motor inverter, meaning it’s an inverter specifically designed to control a three phase permanent magnet motor. When we convert the DC power into an AC waveform, we can now control the frequency and amplitude of the AC waveform. This allows us to vary the AC power to the PM motor thus controlling its speed and torque.

This is why we use an inverter in the Hydrapulse. It allows us to directly control the hydraulic fluid flowrate and pressure by controlling the PM motor speed and torque. All due to the transistors at the heart of our inverter technology.

Motor Speed = Fluid Flowrate

Motor Torque = Hydraulic Pressure

The Most Advanced Electro-Hydraulic Inverter Technology Available

Now that we have a basic understanding of the inverter inside the Hydrapulse Smart HPU, we need to understand why our technology is ready for the fluid power Industry.

What makes the inverter possible is the transistor. It’s the component that turns the power on and off for each leg of the motor. It’s basically just a switch that is controlled by the microprocessor. The microprocessor sends a signal to the transistor’s gate to turn it on or off. (Learn more about field-effect and insulated gate bipolar transistors.)

Where things start to get interesting is when you to consider the transistor type, efficiency and speed at which it switches. Transistors are pretty efficient when they are in their ON or OFF state (like a hydraulic spool valve that is either fully closed or fully open) but they create a lot of heat when they are somewhere in between on and off since they cannot transition instantaneously.

It gets complicated since we turn the transistors on and off extremely quickly in pulses of up to 100,000 or more times per second (Pulse Width Modulation) to create the output AC sine wave we want at any given instant. This creates a lot of on to off transitions, which introduce heat (lost efficiency). Creating a balance between the heat lost and how fast you can switch the transistors on and off is a critical element of the development of an inverter. Every application demands a different approach and our team has spent years making the most efficient inverter possible for the fluid power market.

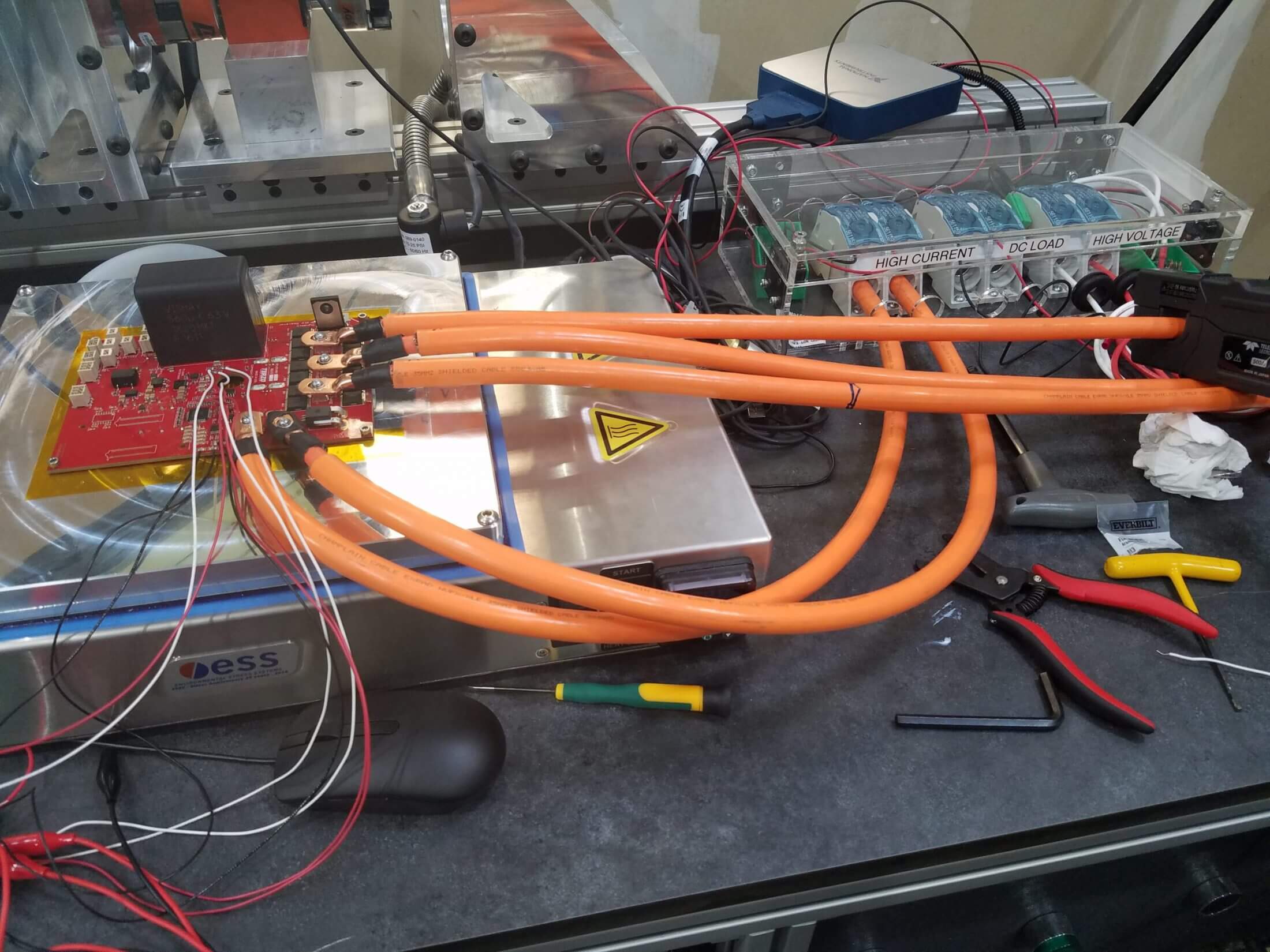

To create a robust and durable product for the off-highway and industrial fluid power market takes transistors that can withstand the temperature and vibration that is common in our industry. That is why we have used the most advanced, automotive grade MOSFET and IGBT transistors available to ensure reliability year-after-year for our customers!

Transistor Cooling

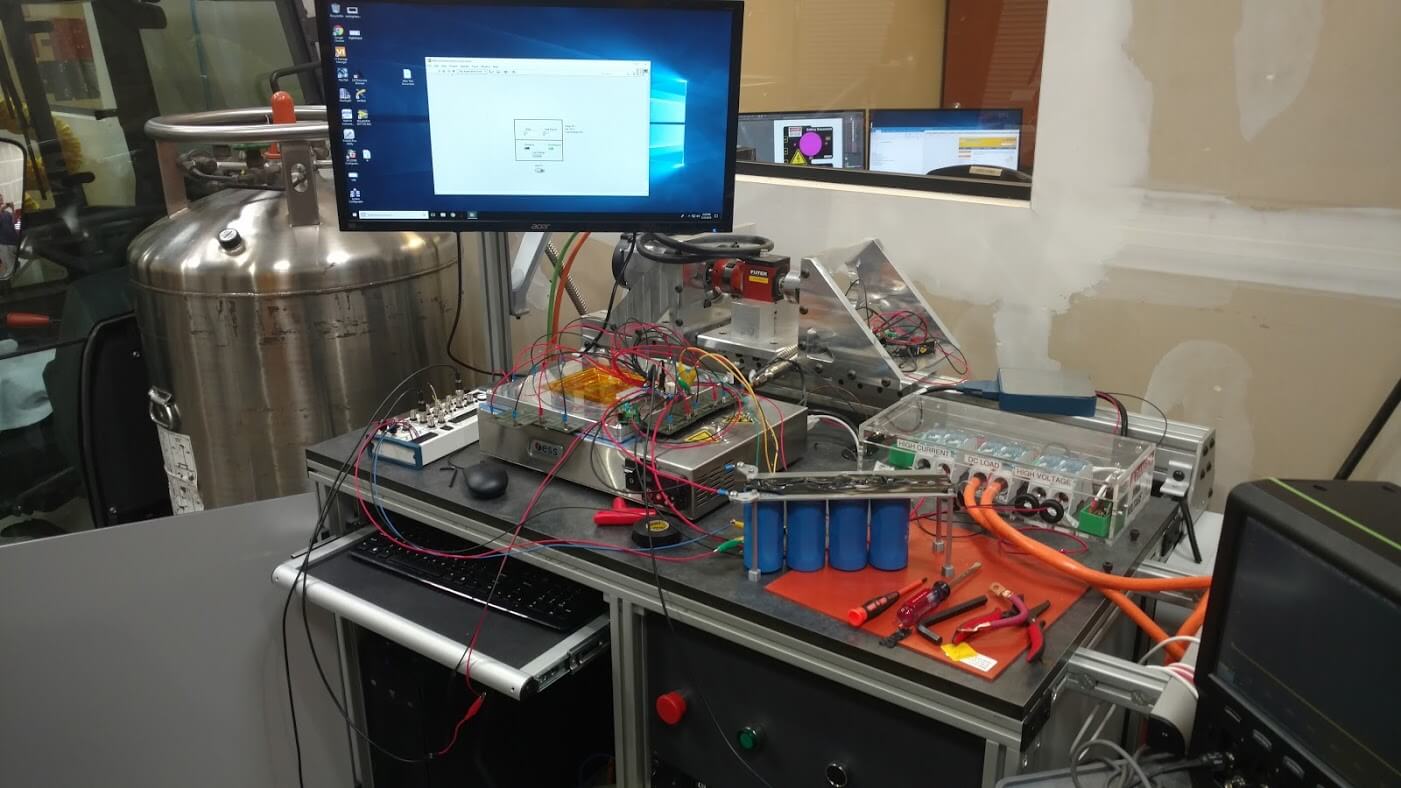

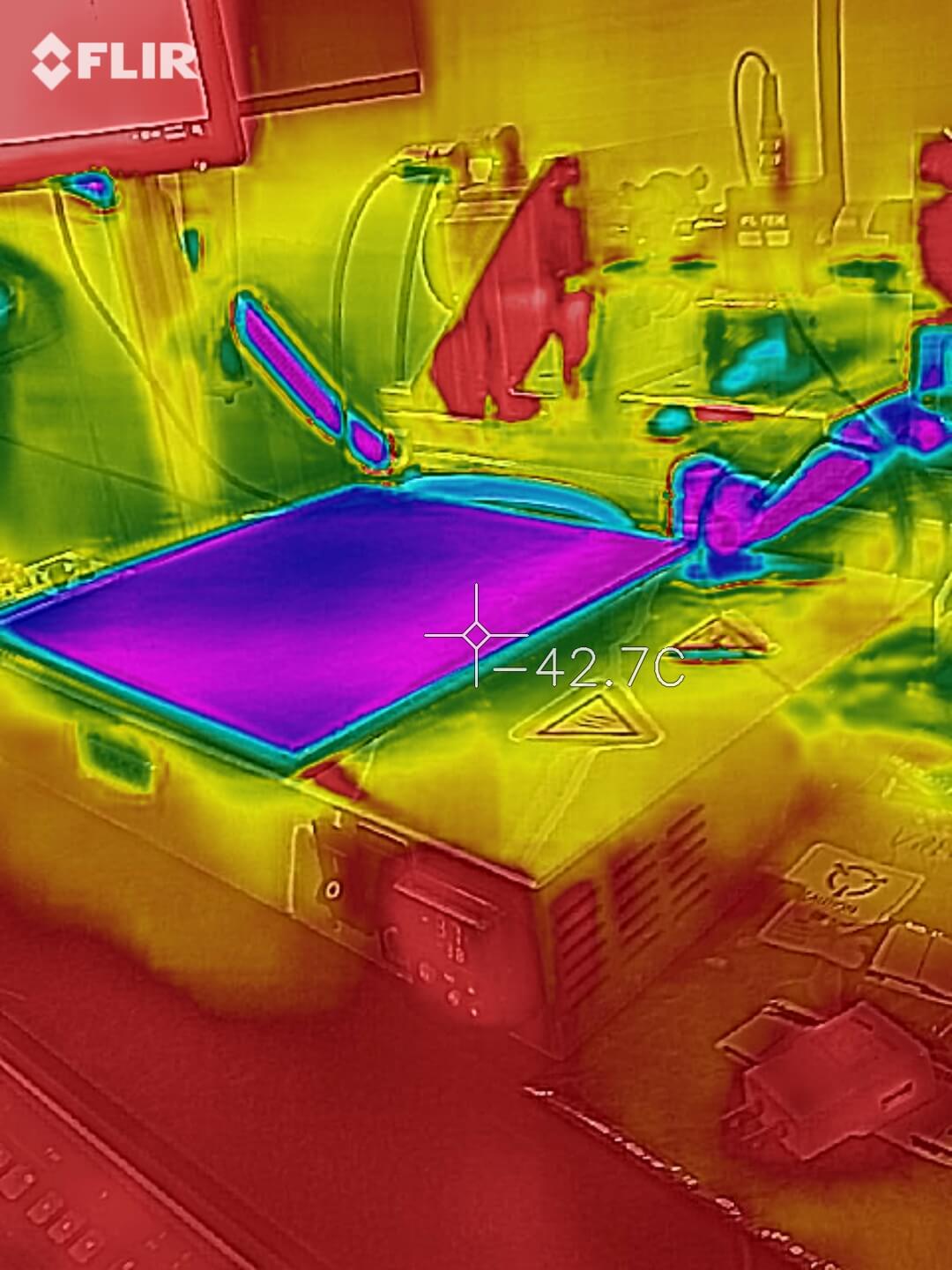

No matter how efficient your design is, there is still some heat to remove from the transistors. Our engineers have spent years working on the best and most economical method of cooling the transistors we use. We started with discrete transistor testing on cryogenic cooled plates to -40°C. This allowed us to characterize all the different transistors on the market to find the best ones for our applications. We determined how to efficiently remove the heat. This was critical since the Hydrapulse is a closed system that is sealed from the environment. You can’t simply put a big fan on a fin heat sink like you do in typical industrial control cabinets. So we made the electro-hydraulic inverter we have today.