Control

HYDRAPULSE® TECHNOLOGY

An Entirely New Level of Control

Hydraulics are all about power and control. How much power can we provide and how much control do we have over that power. Fluid power has always controlled a function with valves, pressure control valves, directional control valves, servo valves, proportional valves, bang bang valves, poppet type valves, spool valves, pilot operated valves, electronically controlled valves, load sense valves, pressure compensated valves, and we are sure there are many more we have left out. By integrating amazing technology, like a hydraulic pressure sensor, into our units, we can provide superior control without the hassle or expense.

But looking at the future, the control of fluid is not about valves, it is about software. Software-controlled hydraulics in the form of the Hydrapulse introduces an entirely new level of control. An infinite level of control is now available without the complexity, lead time, maintenance problems, troubleshooting and cost of traditional hydraulic control valves.

In the end, the entire hydraulic industry boils down to two things: we want an actuator (cylinder) to go in and out at a desired speed and force, and we want a hydraulic motor to go round and round with a desired speed and torque. That is it folks, the entire industry is really that simple…or is it? What makes hydraulics incredibly complex is not the two things we want to actually accomplish, it’s the way we need to accomplish them. The only way is through a complex series of valves that are not only difficult to design, they are sometimes impossible to troubleshoot.

Integrated Hydraulic Pressure Sensor – On each output

Nothing is more powerful for the control of a system than knowing exactly what the variable that you are trying to change is at any given moment in time. This definitely goes for the pressure of a hydraulic system. Many times in modern hydraulic systems, using a pressure transducer (different from a pressure switch) is a cost and labor luxury that is omitted.

This is due to the fact that you cannot simply put a pressure transducer on a fitting. You have to specify the correct transducer, find out the cost, find out the lead time, wire the sensor into some type of control system. Then, you have to program the control system to do something with the pressure reading. This involves software, programming knowledge, troubleshooting, etc. The end result is that our industry usually just leaves it out. Not anymore!

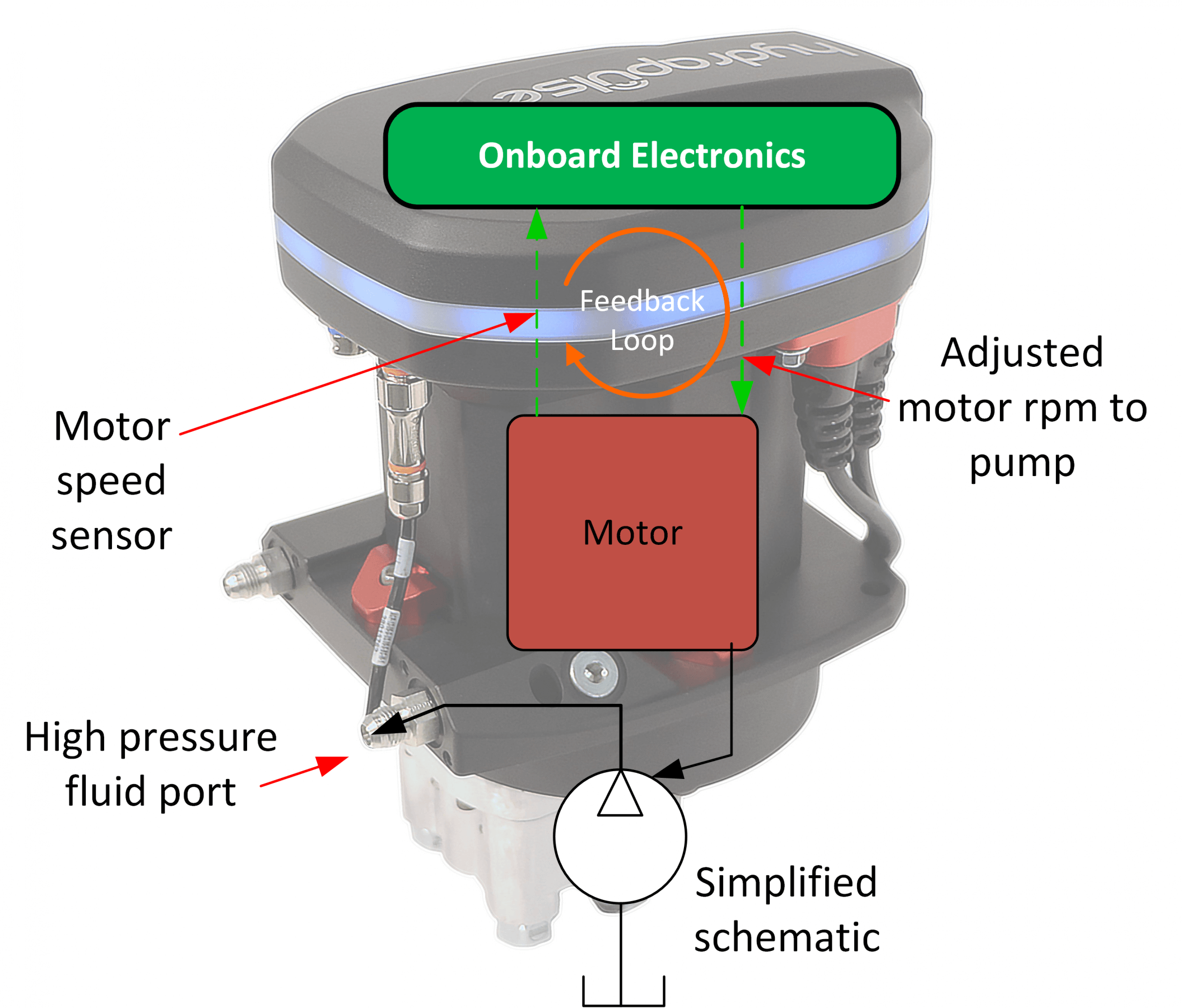

Every single Hydrapulse has two pressure sensors (A and B ports for bi-directional operation) that are constantly monitoring the output pressure and sending a signal back to our on-board electronics and software algorithms to precisely control your work function. You can now simply “dial” in your desired pressure on the fly and at any given time to provide for unparalleled levels of pressure control.

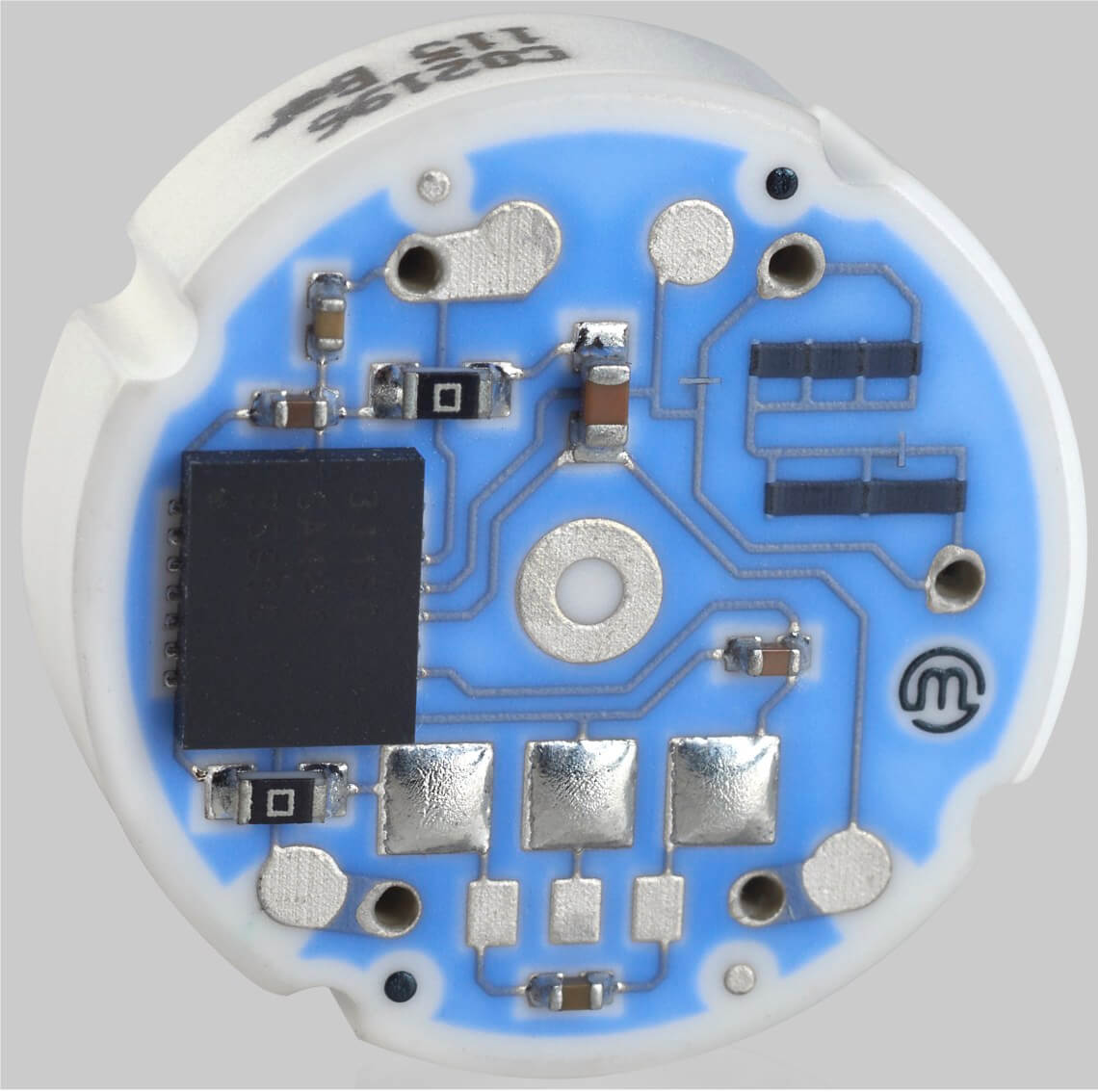

This unique feature of the Hydrapulse technology is accomplished by embedding tiny ceramic pressure sensors into the product that measure the instantaneous pressure of the outlet and we use that reading to adjust our system to meet the desired pressure target that the system is calling for. We do this 100 times per second!

These pressure sensors utilize state of the art piezoresistive technology which is accurate, cost effective, small and powerful.

In addition to providing digital pressure control, this feature also provides a functional safety feature. Our software has a user-defined max pressure setting that can signal alarms or faults for a system when a given pressure spike is sensed or any other unusual pressure condition.

Closing the loop (on flow)

Besides pressure, the other primary metric of hydraulic systems that needs to be controlled is the flowrate. Flowrate is typically discussed in terms of gallons or liters per minute (gpm/lpm). The flowrate in a work function determines how fast an actuator (cylinder) extends or retracts and how fast (rpms) a hydraulic motor turns.

The flowrate or “speed” control is critical for many applications. Traditional systems utilize a load sense pump that controls the amount of flow the pump delivers. This method of controlling flow wastes energy (a load sense pump requires an orifice that creates a pressure drop to send that pressure differential back to the pump swashplate control) and also creates an inherent maintenance issue with complex fluid passages and small orifices that can get plugged partially or completely, leading to all kinds of interesting outcomes.

The team of engineers at Terzo Power Systems have coined a new term: digital load sense! This means that we can set the Hydrapulse to “flow mode” and command a desired flowrate to be delivered regardless of the pressure created by the work function. A constant flowrate is important to maintain a smooth extension on a cylinder even though it is encountering different resistance throughout its stroke

Typical temperature sensor for oil temp measurement on the Hydrapulse

Temperature Control – at last!

Among the many parameters that the Hydrapulse EHPU monitors continuously is a number of temperature sensors. These temperature sensors monitor our power electronics to provide self-protection, our motor windings and other performance conditions. But one temperature sensor that is pretty useful is our oil temp sensor.

We installed a temperature sensor in the coolant oil prior to the heat sinks for monitoring the oil temp. This temperature reading is pretty close to the actual oil temperature in the reservoir and can be used by our customers for the following:

1. Oil reservoir high temperature alarm

2. Oil temp alerts

3. Overheating conditions

4. Failure of a cooling system or degraded cooling system performance

These are just some of the useful system features our customers can utilize without installing any additional temperature switches, temperature sensors, etc.

Just one more value add for the Hydrapulse!