Weight Reduction

Hydrapulse® Technology

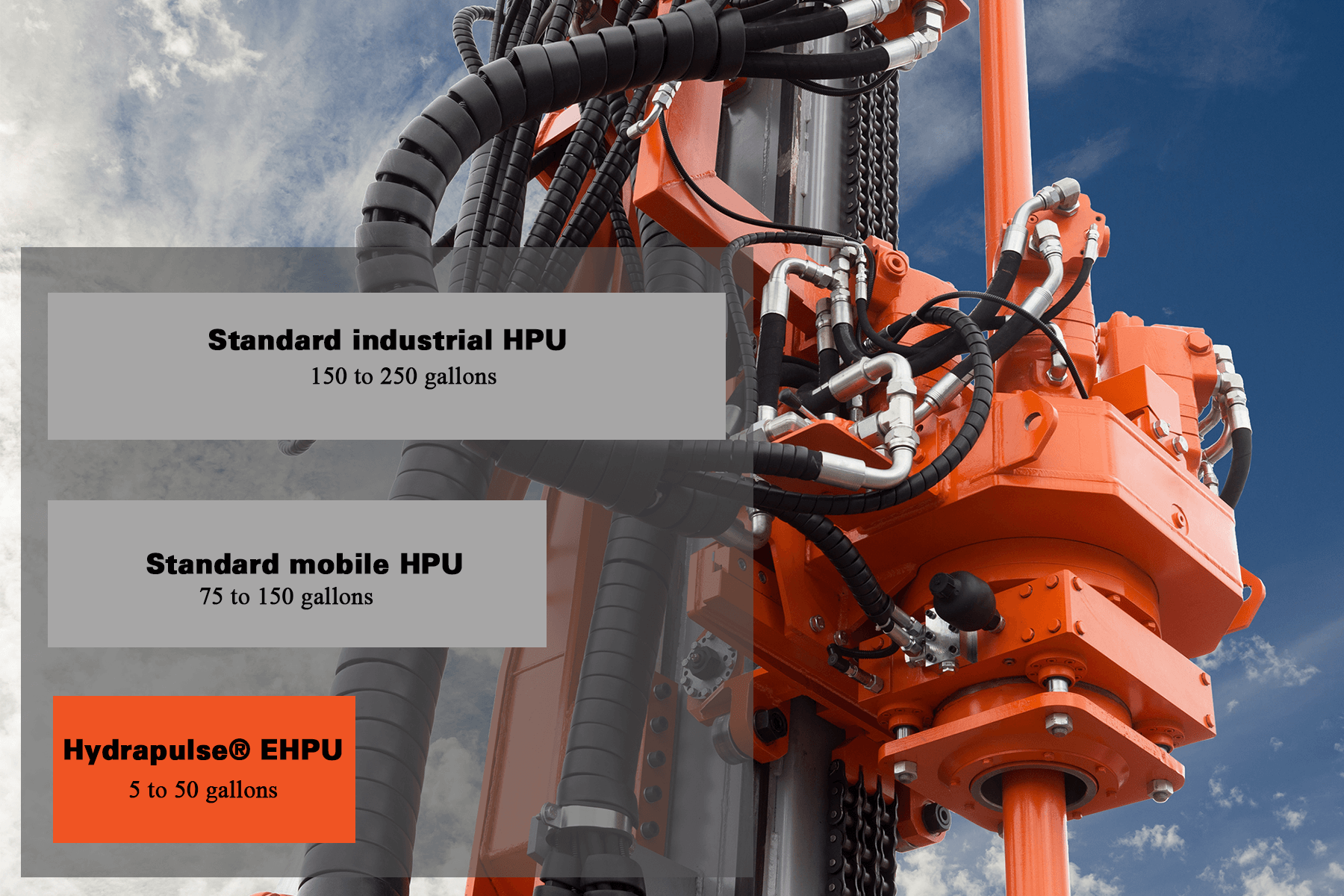

Our Lightweight Hydraulic Pump Delivers Up to 87% Weight Reduction

Many of the reasons our technology is smaller are the same reasons that it is much lighter as well. We discussed our permanent magnet motor system, component reduction by integration, and a few other details in our Size Reduction page but we will go further into detail here on how the Hydrapulse can help substantially reduce the weight of your hydraulic system.

By looking at a complete hydraulic power system and engineering it for the purpose and function it needs to accomplish, Terzo Power Systems has disrupted the traditional way of creating fluid power and provides an industry record-breaking lightweight hydraulic pump for all applications.

We took the essence of what our hydraulic systems are designed to do and boiled it down to its simplest form: we want to precisely control our fluid pressure and we want to precisely control our fluid flow rate. We do this directly with our digital Hydrapulse system. With these two basic yet incredibly powerful tools, we can move the biggest pieces of equipment on earth and we can do it with new levels of efficiency, size and weight!

Oil reduction = weight reduction

Hydraulic oil is the lifeblood of hydraulic systems, in fact it is the fluid in Fluid Power! But hydraulic oil is also heavy, expensive and a safety and environmental hazard when spilled, leaked, or otherwise released from its confinement.

The only oil in most hydraulic systems that can be adjusted is the amount contained in the reservoir. Storing oil in the reservoir serves the primary purpose of creating resonance time (time to remove entrapped air, heat and contamination) within the system. Adequate tank sizing many times comes down to a “rule of thumb.” I have heard anything from 3-8 times the flowrate of the system for industrial applications down to 1x or 2x the flowrate for mobile systems (plus 10% for air space). Regardless of this, it would be generally agreed upon that if you can reduce your heat generation in the system, you should be able to downsize your reservoir accordingly.

By creating a significantly more efficient system with our Hydrapulse power-on-demand technology, the heat generated is reduced and therefore the size of the reservoir is also reduced. In fact, with a properly designed Hydrapulse system, the oil requirements can be reduced by over 75% in many applications. This is not only good for weight reduction, but it’s also good for the wallet and the environment. Where we come from, that is a win-win.